|

|

|

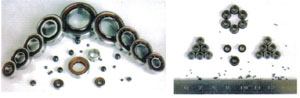

Ceramic Bearing and Bearing Ball

Ceramic material are noted for their characters of high strength in high temperature, good wearability, high rigidity, corrosion resistance, high  temperature resistance, electrical insulation, non-magnetic, there characters qualify them for replacing steel to make bearing to meet the requirements in a severe condition where a steel bearing can¡¯t wyghstand. Ceramics material which can be used in making bearings, in clued mainly Silicon carbide(SiC), Silicon Nitride(Si3N4), Zirconia(ZrO2) and Alumina(Al2O3) etc. Si3N4 is in speaking form, which bearing steel also has but ZrO2 and Al2O3 fail in a crush form, a catastrophic failure. They are temperature resistance, electrical insulation, non-magnetic, there characters qualify them for replacing steel to make bearing to meet the requirements in a severe condition where a steel bearing can¡¯t wyghstand. Ceramics material which can be used in making bearings, in clued mainly Silicon carbide(SiC), Silicon Nitride(Si3N4), Zirconia(ZrO2) and Alumina(Al2O3) etc. Si3N4 is in speaking form, which bearing steel also has but ZrO2 and Al2O3 fail in a crush form, a catastrophic failure. They are  mainly used for the transmit device of high temperature furnaces; high-speed rotation field; aviation and airspace fields; the main shaft of machine tools; chemical machinery, food industry and marine industry; high vacuum field; strong magnetic environment; roller skates, model airplanes and motor-driven toys so on in civil use etc. mainly used for the transmit device of high temperature furnaces; high-speed rotation field; aviation and airspace fields; the main shaft of machine tools; chemical machinery, food industry and marine industry; high vacuum field; strong magnetic environment; roller skates, model airplanes and motor-driven toys so on in civil use etc.

Specification

| |

Bearing

steel |

Stainless

steel |

Si3N4 |

ZrO2 |

SiC |

Al2O3 |

Density g/cm3 |

7.85 |

7.9 |

3.20-3.30 |

6.00 |

3.10 |

3.95 |

Coefficient of linear expansion 10-6/K |

10.0 |

11.0 |

3.2 |

10.5 |

4.5 |

8.5 |

Poisson's ratio |

0.30 |

0.30 |

0.26 |

0.30 |

0.20 |

0.22 |

Hardness

HV HRC |

700

60-66 |

55-60 |

1300-1600

75-80 |

1000-1200

70 |

2500min

85-90 |

1600-1800

80 |

Bending strength Mpa |

2400 |

|

600-1000 |

950-1200 |

450 min |

300-500 |

Fracture toughness Mpam1/2 |

25 |

|

5.0-7.0 |

8.0-10.0 |

3.0-4.0 |

3.0-4.0 |

Thermal conductivity

W/mk |

30-40 |

15 |

35 |

2-3 |

150 |

30 |

Special electrical

resistance

¦¸ mm2/m |

0.1-1 |

0.75 |

108-1018 |

105-1015 |

10-103 |

108-1018 |

Max working

temperature ¡æ |

120 |

300 |

800 |

|

1400 |

|

Corrosion resistance |

poor |

poor |

good |

good |

good |

Good |

Stress cycles

(50% failed) |

107 |

|

107-109 |

105 |

|

|

No lubrication friction |

Large |

Large |

Little |

Little |

Little |

|

Magnetism |

Magnetism |

Magnetic |

No |

No |

No |

No |

Centrifugal force |

Very large |

Very large |

Little |

Large |

Little |

Middle |

Operate temperature

increasing |

High |

High |

Low |

|

Low |

|

Size stability |

Unstable |

Unstable |

Stable |

Unstable |

Stable |

Unstable |

Conductivity |

Conductor |

Conductor |

Insulator |

Insulator |

Conductor |

Insulator |

Rolling contact failure form |

Spalling |

Spalling |

Spalling |

Crush |

Crush |

Crush |

|